Have you ever thought about what makes a good work instruction or how a good work instruction improves work effectiveness?

Work Instructions are “where the rubber hits the road”. Good work instructions put all the work of developing maintenance strategies and tactics, planning and scheduling into action.

Objectives for work instructions should be to ensure the tasks are done safely, effectively and efficiently with a high level of quality and repeatability.

Hence, good work instructions provide:

- Improved safety performance of maintainers

- Improved productivity of maintainers by reducing the need to obtain parts or materials part way through PM inspections,

- Improved productivity of maintainers by reducing unplanned work and downtime by specifying what should be done if acceptable conditions are not met,

- Improved productivity of maintainers and availability of equipment by reducing re-work,

- Improved equipment availability and reliability by identifying potential failures.

General aspects of good work instructions

Some general aspects that must be included in work instructions include:

- Wording must be clear, precise and easily read. Sentences should be short and to the point. Pictures and diagrams can greatly assist (as per the old saying “a picture is worth a thousand words”). This is very important if the maintainers’ first language is not English.

- Text to be written using uppercase and lower case letters, not just upper case.

- Text and pictures must be clear and large enough for the majority of maintainers to see easily, some will need glasses to read. Very small, grainy of blurred pictures and diagrams are of little or no use. Note that a lot of high definition pictures and diagrams greatly increase the electronic storage size of the document.

- Where a reference to another document is necessary (e.g. a workshop manual), then a copy of the relevant parts of the workshop manual MUST be provided to the maintainer with the work instruction. People cannot be expected to accurately remember complex instructions.

- Emphasis of critical tasks with safety or work quality implications is required.

Example: The following are placed with the appropriate task and description of the hazard.

Types of work instructions

There are two main areas of maintenance where work instructions are needed:

- Preventive Maintenance (PM) schedules that include inspections, condition monitoring, services and testing

- Corrective maintenance including repairs and replacements

PM schedule work instructions

PM schedules contain three types of tasks:

- On-condition

- Fixed Interval

- Failure Finding

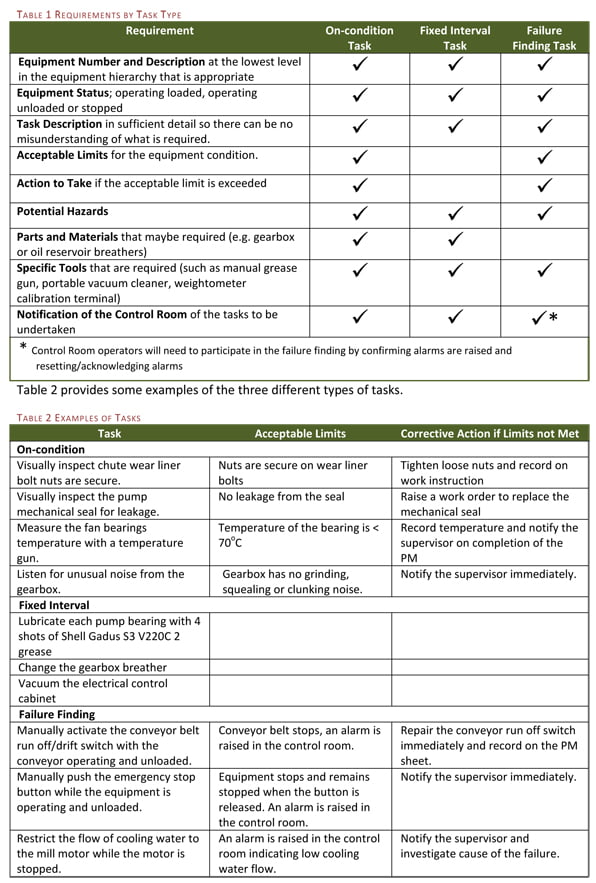

Each task type has slightly different requirements when included in a work instruction, but can be easily accommodated in a single document.

On-condition tasks

On-condition tasks are used to address specific failure modes of equipment and in most cases seek to determine the condition of equipment and more specifically identifying potential failures associated with the failure mode. This can include inspections, measurements and condition monitoring.

Fixed interval tasks

Fixed interval tasks are used to address failure modes where the wear-out or failure life is well known and the tasks are performed irrespective of condition. These include component change outs that are either refurbished or discarded (as determined during the earlier task development stage), cleaning, lubrication, calibration and adjustments.

Failure finding tasks

Failure finding tasks are used to detect failures of protective device. These can be safety related devices or equipment protection devices. Tasks can include manually activating the device such as pull wires on conveyors or limit switches, artificially simulating conditions for the devices such as using synthetic smoke to test smoke detectors, restricting flow for low flow switches, lowering or raising levels for level switches, injecting electrical current into high voltage overloads or circuit breakers.

Table 1 shows the requirements for each task type. The key difference is Fixed Interval tasks do not have “Acceptable Limits” or “Action to Take”. A minor difference is Failure Finding tasks rarely include parts unless a specific device to be tested is known to fail regularly, in which case, a defect elimination action should be initiated.

Task sequencing

Work instructions can include multiple tasks including on-condition, fixed interval, failure-finding, operating loaded, operating unloaded and stopped tasks. The sequence of performing the tasks must be determined prior to using the work instruction in the live system. This is usually best done by walking the proposed route to ensure there is minimal backtracking, particularly if climbing stairs or ladders is involved and suitable access is available.

Corrective maintenance work instructions

Correct maintenance is work that needs to be undertaken because of PM inspections, condition monitoring or a failure.

Work instructions are normally only used for complex or difficult corrective maintenance. OEMs often provide detailed instructions for maintenance of their equipment in the form of workshop manuals or procedures.

Where a work instruction is required, this should contain:

- The equipment number and description at the lowest level in the equipment hierarchy that is appropriate

- Equipment isolation and preparation for maintenance (such as releasing stored hydraulic pressure)

- A sequence and description of the tasks in sufficient detail so there can be no misunderstanding of what is required.

- Specifications pertaining to individual tasks (such as bolt tightening torque requirements)

- Warnings of potential hazards for the maintainer or damage to the equipment while undertaking particular tasks

- Tips on how best to undertake the task (such as positioning or handling).

- Pictures and diagrams can be very useful, particularly if there is likely to be uncertainty with the task.

- Parts required including Stock Numbers or Manufacturers Numbers

- Specific tools required

Level of detail

When developing work instructions a key consideration is the skill and experience levels of your maintainers.

A relatively low turnover rate workforce with relevant trade qualifications and a first language of English requires less detail in how to perform basic tasks. The emphasis should be on what specific tasks are required, any measurements or specifications that apply, reminders of any hazards, tips on how others have determine the best way of undertaking the task and the sequence of tasks. Specific tools and/or parts required can also be included.

A workforce that has a high turnover rate that may or may not have relevant trade qualifications and the first language is not English requires more detail in how to perform basic tasks. More work is required to produce these work instructions that may need numerous pictures and diagrams, details of how to perform basic tasks and may need translation into the local language.

Continuous improvement

Work instructions need space next to or near most tasks for comments, observations and measurements.

Additionally, space needs to be available at the end of the work instruction for the maintainer to add comments regarding improvements to the work instruction. Over time, equipment is changed and part numbers change, plant configuration is modified with access changed; these need to be incorporated into the work instructions on an on-going process.

Customer Service research has shown that if changes are made within two weeks and the customer (maintainer) is notified the customer is highly satisfied and will display a positive attitude. If the response is in excess of two weeks, the customer (maintainer) becomes increasingly dissatisfied and is likely to exhibit negative attitudes.

Good work instructions improve your overall maintenance performance.