During the past decade, the “Lean” phenomenon has enabled manufacturing industries to greatly increase their levels of profitability and productivity. Combined with other initiatives such as Total Productive Maintenance (TPM), Lean has encouraged these companies to focus on the efficiency of their production processes.

In the maintenance environment, our experience has been that, while the same underlying principles apply, the way in which they are applied needs to be modified from that typically applied in a discrete manufacturing environment if maximum results are to be achieved. A lean maintenance approach cannot just be a mirror image of a Lean production approach.

Why implement lean maintenance?

Many organisations have fallen into the trap of concentrating on the tools and techniques associated with Lean instead of the reason for their use. In simplistic terms Lean Maintenance is:

- Doing the right maintenance and,

- Doing those activities in the most effective and efficient manner.

Lean Maintenance is a powerful approach to help identify and eliminate waste related issues and deliver real bottom line improvements if implemented and managed in the right way.

Integrated lean maintenance improvement approach

The integrated Lean Maintenance improvement approach that we recommend and use applies the Lean principles in an appropriate framework specifically adapted for their application to maintenance. This ensures that the principles are applied in the most time and cost-effective manner that is appropriate, and also leads to rapid, measurable improvements in bottom-line performance. The framework can be adapted further to fit the specific requirements of individual organisations and their specific issues.

From our experience of implementing Lean and TPM orientated improvement initiatives we advocate a twin-streamed approach – with each stream addressing the overall objectives of eliminating waste from a slightly different angle, as follows:

Stream 1: Rapid waste-focused improvement

This aspect of our approach will:

- Integrate Lean Maintenance into an existing improvement process to avoid it becoming just another initiative.

- Train and mentor key personnel from within your organisation to lead the Lean maintenance projects.

- Concentrate on reducing waste that is having the most significant contribution towards failure to achieve production output and cost target

- Focus on maintenance specific areas of waste. These will include:

- Unproductive work – Efficiently doing work that doesn’t need to be done.

- Delays in motion – Waiting times, delays waiting for parts, machinery, people, etc.

- Unnecessary motion – Unneeded travel, unnecessary movement of mobile assets, trips to tool stores or workshops, looking for items, moving mobile work stations around without good reason.

- Poor management of inventory – Not able to have the right parts at the right time. A complex area that can cause many of the other areas of waste on this list.

- Rework – Having to repeat tasks, or do additional tasks, as a result of poor workmanship.

- Underutilisation of people – Using people to the limits of their qualifications, not to the limits of their abilities.

- Ineffective data management – Collecting data that is of no use, or failure to collect data which is vital.

- Misapplication of machinery – Incorrect operation or deliberate operational strategies leading to high cost or maintenance work being done when it needn’t be.

- Utilise tools and techniques which align with the elimination of waste detailed above. The order in which they are introduced is heavily reliant on understanding maintenance related waste and what should be addressed to deliver real bottom line value. These include:

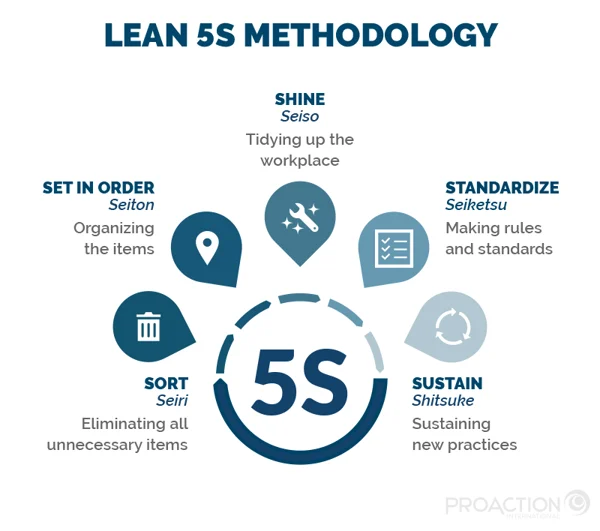

- 5S

- Visual Work Place

- Value Stream Mapping

- Mistake Proofing

- Standard Work

- Planning & Scheduling

- RCM/PMO

- Implement an improvement cycle based around a predefined timeframe (usually 10 to 12 weeks).

Stream 2: Business process and systems improvement

This aspect of our approach will:

- Set-up a governance program to ensure it delivers measurable, sustainable improvements in organisational performance.

- Deal with organisation-wide waste associated with business process, system, technology, people and technical issues that are impacting on the ability to achieve production and cost targets, and lay the foundations for future sustainable improvements.

The benefits of lean maintenance

The benefits of utilising this type of approach are:

- Full implementation of targeted lean improvement projects over a 12 month period.

- Rapid achievement of measurable performance improvements in the short term.

- A lean program that can be managed and monitored which will ensure improvements are sustained over the long-term.

- Consistency of approach for future Lean improvement projects.

- Fully trained personnel in the principles of Lean maintenance.

- Site wide exposure of Lean maintenance through demonstrating the benefits and not just the tools and techniques. We find this is the best way to disseminate the approach through all the levels of an organisation.

For more information on Lean Maintenance and how we could help you deliver real sustainable improvements, contact us.

If you enjoyed this article and want to receive notifications of future articles that we publish, please sign up for our newsletter here.